- JEERUN

- CHINA

- 3weeks

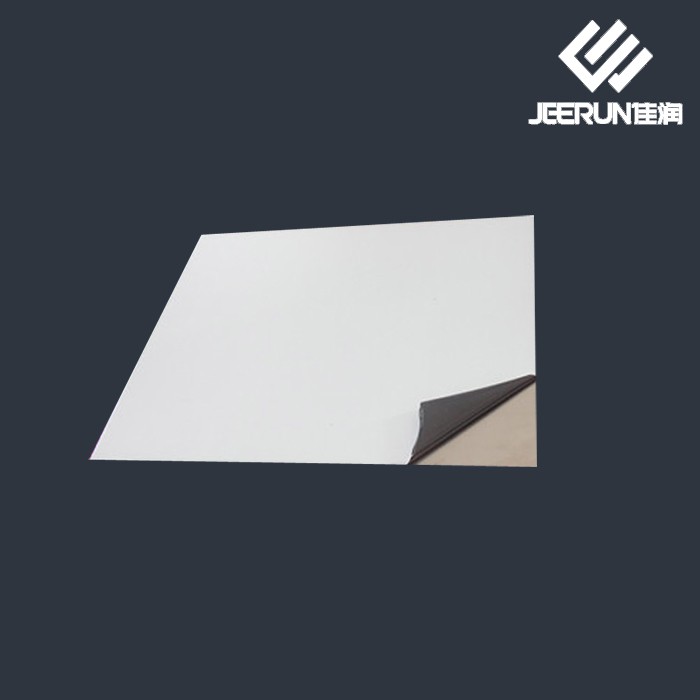

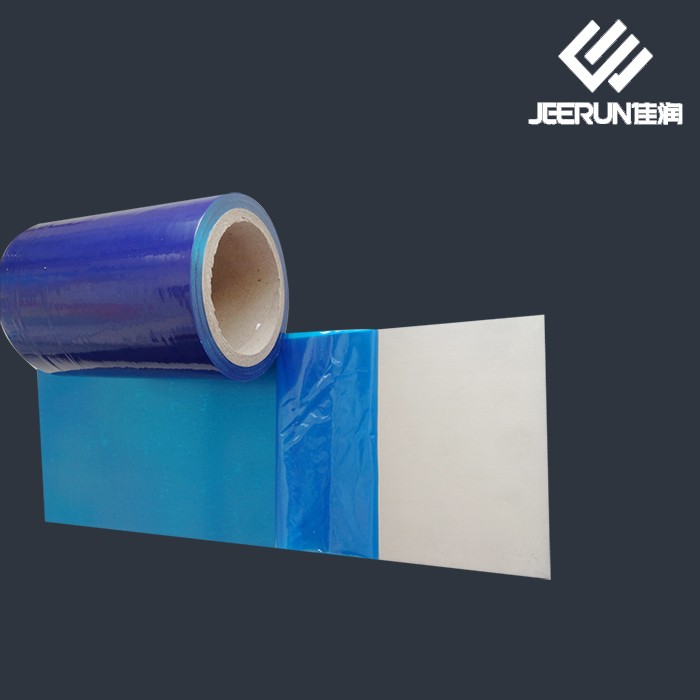

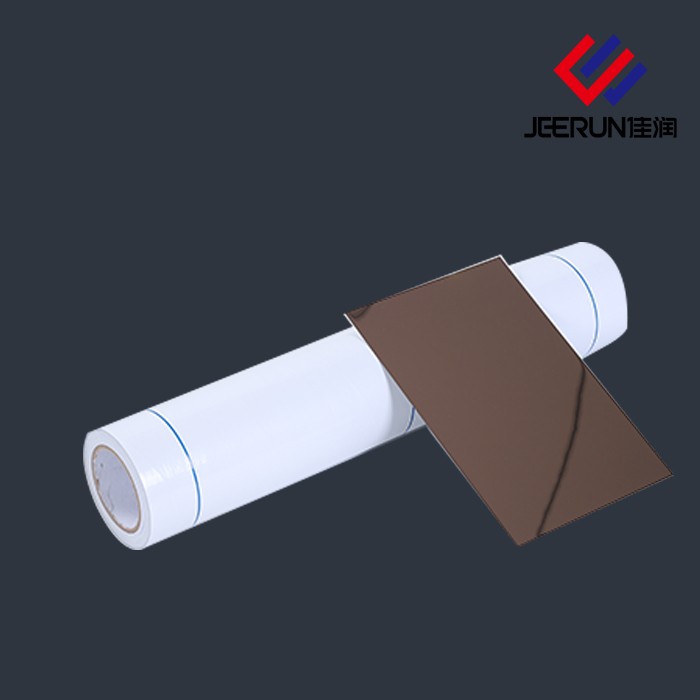

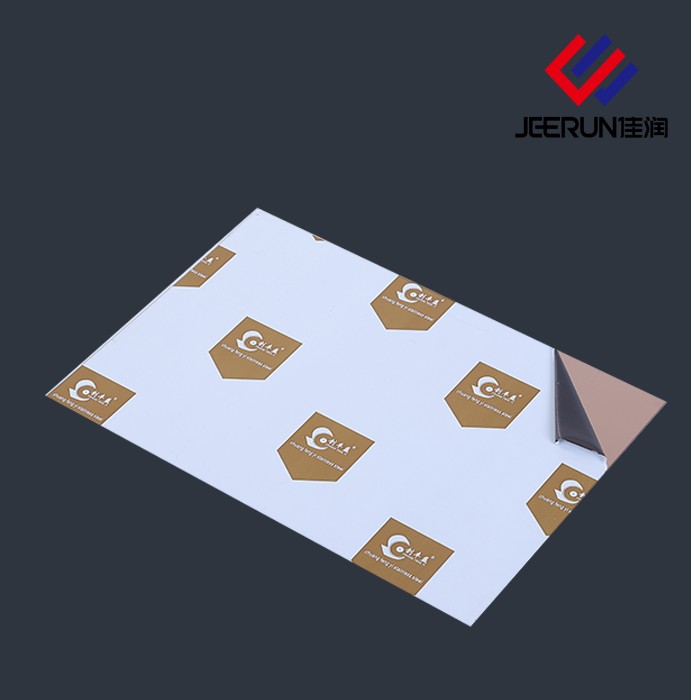

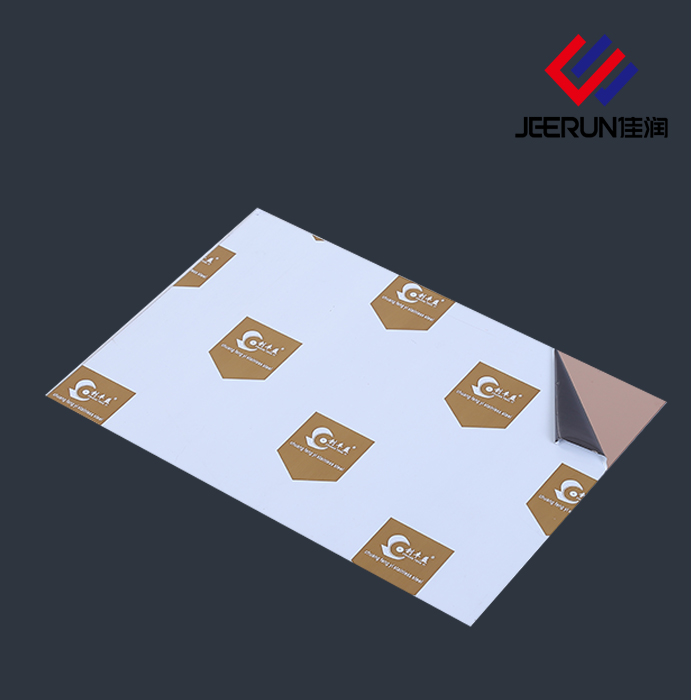

Protective Foil For Stainless Steel BA Finish

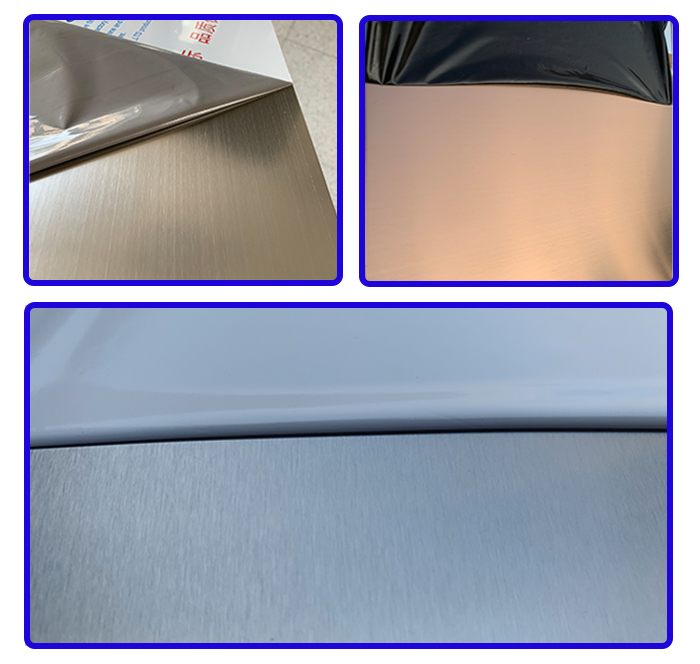

1. 100% pure PE raw material

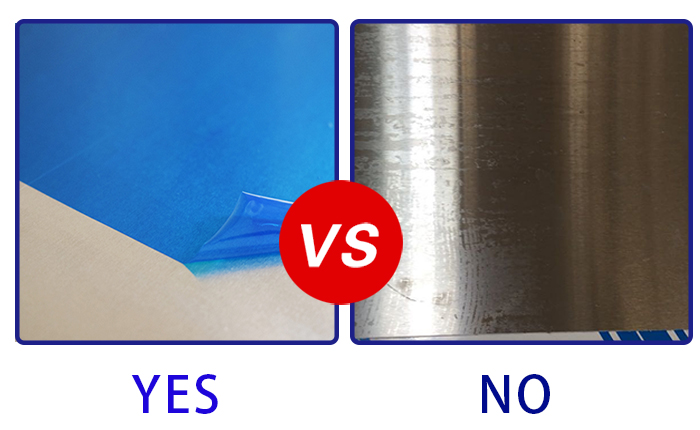

2. Special adhesive(glue) for stainless steel BA finish and there is no trace or pollution on surface after peeling off.

3. There is no glue remaining on sheet after removing protective foil.

Protective Foil For Stainless Steel BA Finish

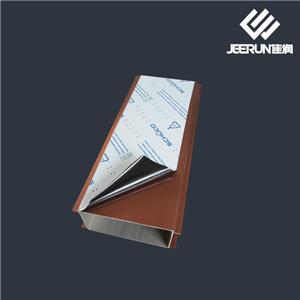

Black and white protection film is the most common protection film for stainless steel. It is used on stainless steel HL, 2B, BA, NO.3, NO.4, Mirror finish to protect the sheet from damage, dirt and pollution during transportation and stallation. It will be removed after installation.

| Product | Protective Foil For Stainless Steel BA Finish |

| Backing film | PE |

| Adhesive type | water-based acrylic |

| Color of film | black and white |

| (clear, blue, milk white, red etc. available) | |

| Printing | No printing or printing in 1-4colors |

| Thickness | 80microns (40microns-100microns available) |

| Width | 500-2000mm |

| Length | 200-1000m/roll |

| 180° peel strength | 20-500g/25mm |

| Tensile strength MD | ≥25N/2cm |

| Elongation at Break MD | ≥380% |

| UV resistance | 45days or 6months |

| Shelf life | 12months from production date |

| Application | Low adhesion for Mirror finish |

| Medium adhesion for HL, BA, 2B finishes | |

| High adhesion for NO.3, NO.4 finishes |

SHANDONG JIARUN NEW MATERIAL CO., LTD, covering an area of 66600 square meters, has specialized in Protective Foil For Stainless Steel BA Finish over 18years. Having staff approx. 300 people, film blowing machine 18sets, printing machine 9sets and coating line 9sets, JEERUN has become one of top 5 suppliers of protective film and other kind of PE film in China.

Drying process of Protective Foil For Stainless Steel BA Finish is the key production process to determine whether it will leave residue. JEERUN takes five steps to control and inspect drying process to ensure no residue.

On-line inspection of each roll during drying process by front-line workers.

On-line inspection randomly during drying process by QC

Water immersion test by 2*24h after drying process by QC

High temperature and humidity test Temp 65℃ RH 90% 7*24h by QC

Anti aging test Temp 74℃ 7*24h by QC