- JEERUN

- CHINA

- 2weeks

- 26million m2/month

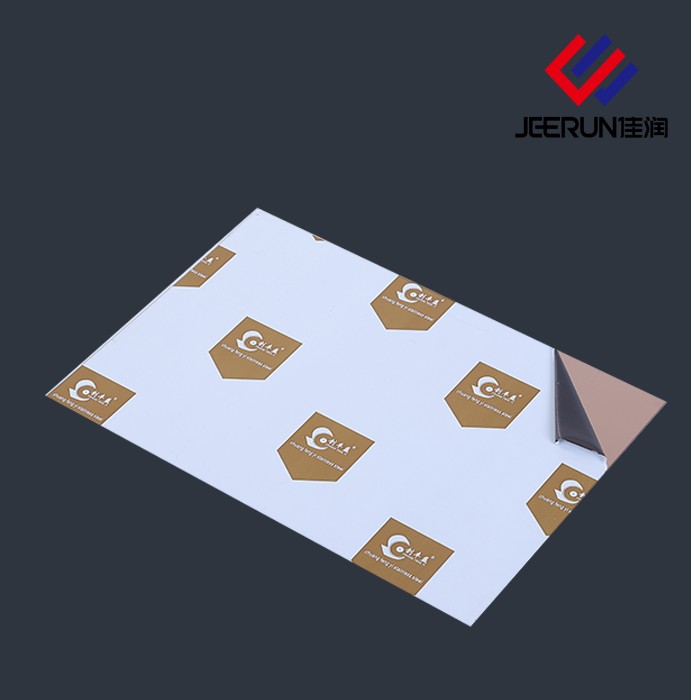

Black And White Protection Film For Stainless Steel HL Finish

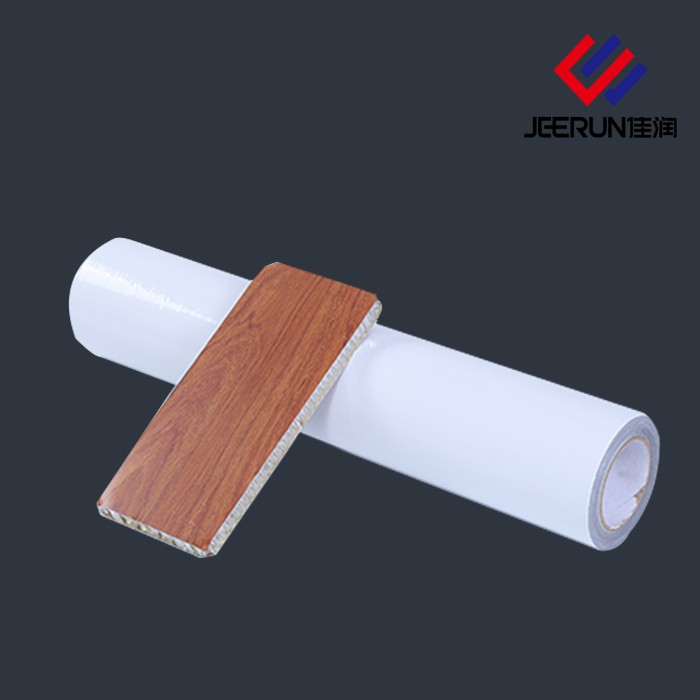

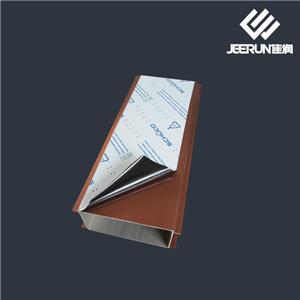

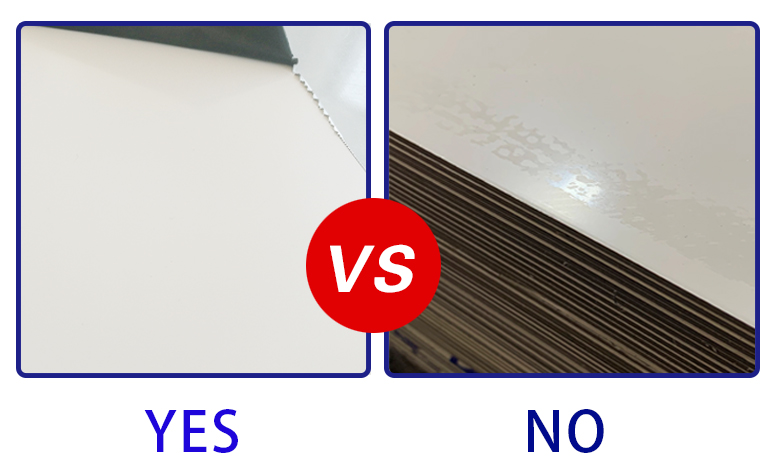

1. Special adhesive for BA, 2B, HL finishes and there is no trace or pollution on target surface.

2. Strict production process control and quality control, there is no residue problem.

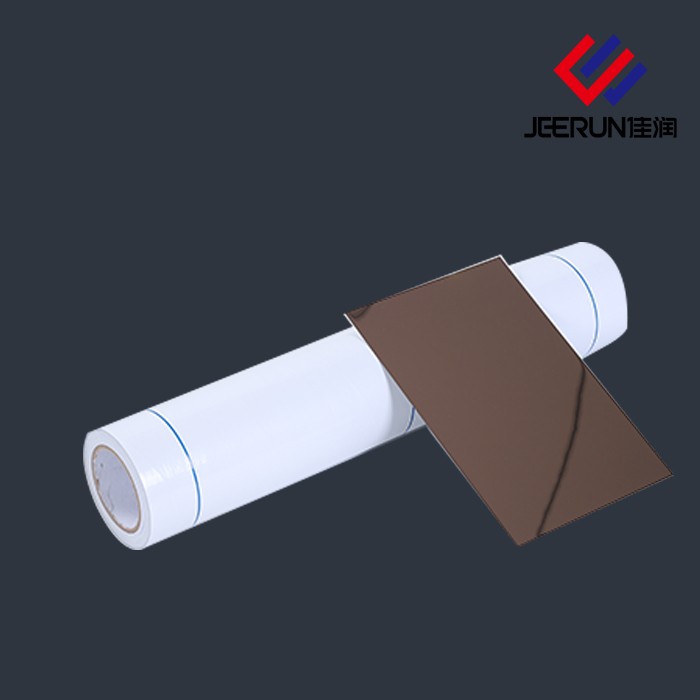

Black and White Protection Film For Stainless Steel HL Finish

Black and white protection film is the most common protection film for stainless steel. It is used on stainless steel HL, 2B, BA, NO.3, NO.4, Mirror finish to protect the sheet from damage, dirt and pollution during transportation and stallation. It will be removed after installation.

| Product | Black and White Protection Film For |

| Stainless Steel HL Finish | |

| Backing film | PE |

| Adhesive type | water-based acrylic |

| Color of film | black and white |

| (clear, blue, milk white, red etc. available) | |

| Printing | No printing or printing in 1-4colors |

| Thickness | 70microns (40microns-100microns available) |

| Width | 500-2000mm |

| Length | 200-1000m/roll |

| 180° peel strength | 20-500g/25mm |

| Tensile strength MD | ≥25N/2cm |

| Elongation at Break MD | ≥380% |

| UV resistance | 45days or 6months |

| Shelf life | 12months from production date |

| Application | Low adhesion for Mirror finish |

| Medium adhesion for HL, BA, 2B finishes | |

| High adhesion for NO.3, NO.4 finishes |

SHANDONG JIARUN NEW MATERIAL CO., LTD, covering an area of 66600square meters, has specialized in PE protection film over 18years. Having staff approx. 300 people, film blowing machine 18sets, printing machine 9sets and coating line 9sets, JEERUN has become one of top 5 suppliers of protective film and other kind of PE film in China.

For Black and White Protection Film For Stainless Steel HL Finish, we use 100% pure LDPE and LLDPE, which are from SINOPEC, CNPC, SABIC etc. to ensure the quality of PE film.

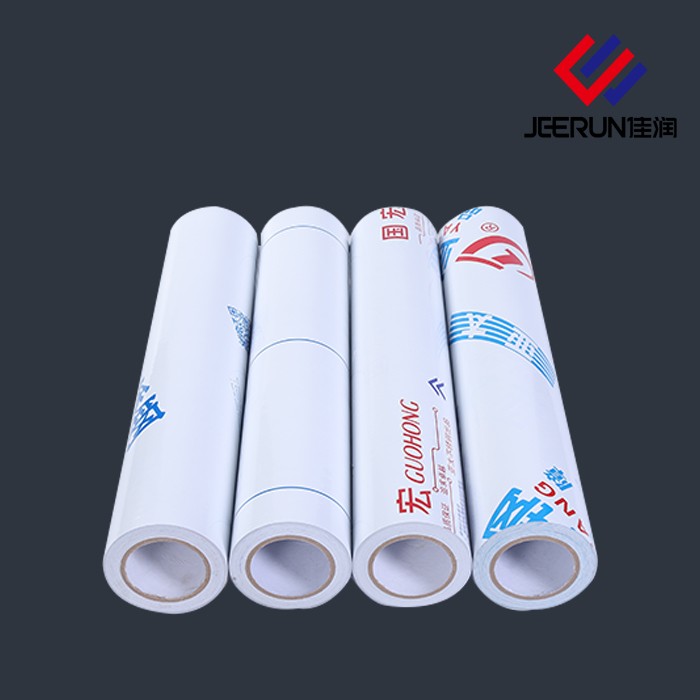

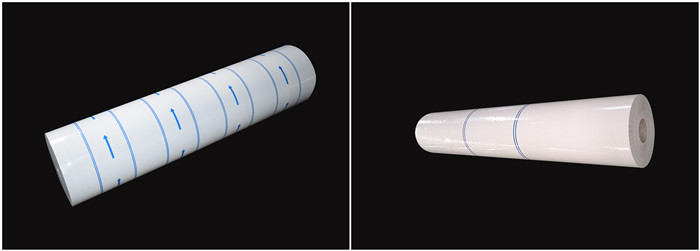

Film blowing is the first producion process of black and white protection film. We have 17 sets of three layers co-extrusion film blowing machines and 1 set of five layers co-extrusion film blowing machine. Black and white color is the most common color because of its excellent aging resistance performance.

JEERUN's printing workshop, covering an area of 2700m2, has 9 sets of printing machines. All our printed items have two payers, one is backing film with logo and the other layer is clear PE film to protect the printed logo. Five colors design like BERCERS logo is available.

Drying process of black and White Protection Film For Stainless Steel is the key production process to determine whether it will leave residue. JEERUN takes five steps to control and inspect drying process to ensure no residue.

On-line inspection of each roll during drying process by front-line workers.

On-line inspection randomly during drying process by QC

Water immersion test by 2*24h after drying process by QC

High temperature and humidity test Temp 65℃ RH 90% 7*24h by QC

Anti aging test Temp 74℃ 7*24h by QC

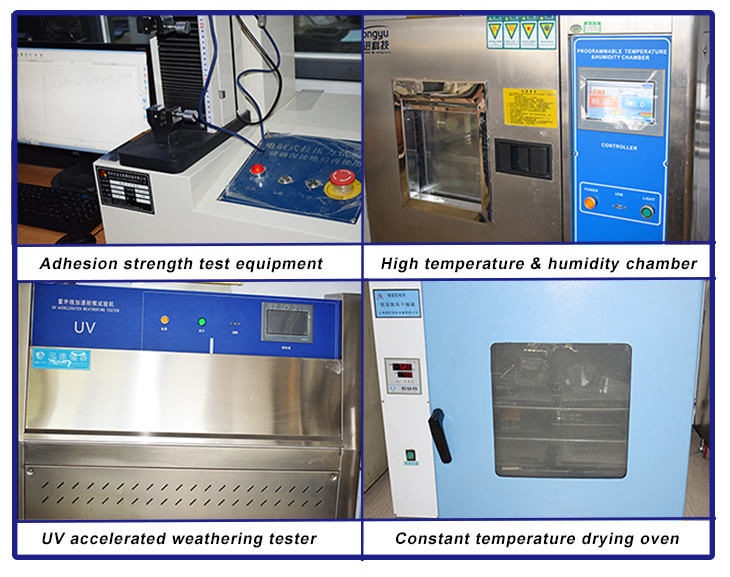

JEERUN has full set of test equipments including vancometer, roughness tester, adhesion strength test equipment, UV weathering tester, high temperature & humidity chamber etc. to check and inpect all kinds of panels from clients, raw materials, semi-finished products and black and white protection film. Togetehr with strict quality control process, we have been always practicing our company's philosophy "Do not bring any troubles to the clients".

For packaging of protection film for stainless steel HL finish, our normal pack as below:

1. plastic core with inner diameter 78mm (paper color is available)

2. Moistureproof PE film

3. Corrugated paper to avoid damage (carton box is available)

4. Fumigation-free plywood pallets

For the ways of loading black and white protection film, we have two main methods.

Method I: All rolls are palletized on plywoods. One 20GP can load about 230rolls with standard size (out diameter of the roll approx. 27-28cm).

Method II: Some rolls are pallerized on plywoods. The rest lie above the pallets in bulk. One 20GP can load about 250rolls.